How AI is Reshaping Supplier Performance and Risk Management

Executive Summary: Modern supply chains are navigating a web of interconnected, high-velocity threats. Traditional, reactive procurement models are no longer sufficient. This article explores how Artificial Intelligence (AI) is transforming risk management from a descriptive function into a predictive strategic advantage, delivering verified ROI and operational resilience.

1. The New Reality: Why Legacy Models are Failing

The operational landscape for procurement has shifted fundamentally. We have moved from a world of discrete risks to a multipolar environment defined by systemic fragility—where a regional conflict or cyber-attack cascades into global logistics failure.

According to recent industry research, 70% of Chief Procurement Officers (CPOs) report that procurement risks are rising. Yet, many organizations still rely on tools designed for a stable era:

- Spreadsheet-based tracking: Creates data silos and bottlenecks.

- Subjective self-assessments: Relies on biased supplier reporting.

- Periodic reviews: Quarterly audits that miss real-time threats.

These legacy methods are not just inefficient; they are dangerous. They force organizations into a “wait and see” posture, scrambling to triage disruptions only after they have impacted the bottom line.

2. The Paradigm Shift: From Triage to Foresight

AI does not merely speed up existing processes; it rearchitects the risk management mindset. It moves the discipline from reactive triage to predictive foresight.

By integrating data from ERPs, IoT devices, and external market feeds, AI creates a “unified intelligence architecture.” The table below outlines this critical operational shift:

| Feature |

Traditional (Pre-AI) Approach |

AI-Driven Predictive Paradigm |

| Data Source |

Historical reports & self-assessments |

Real-time sensors, geopolitical signals, market trends |

| Speed |

Weekly or monthly manual aggregation |

Continuous, “always-on” monitoring |

| Focus |

Reactive response (Post-Disruption) |

Proactive intervention (Pre-Disruption) |

| Scoring |

Static, financial-heavy snapshots |

Dynamic, multi-factor (ESG, Cyber, Geopolitical) |

3. High-Impact Applications: The Data-Driven Use Cases

The true value of AI lies in its specific applications. Below are three key areas where AI is reshaping supplier performance.

A. Predictive Disruption Forecasting

AI models analyze weather patterns, port congestion, and traffic data to forecast delays 48 to 72 hours in advance.

- The Benefit: This foresight enables teams to reroute shipments or adjust inventory before a bottleneck occurs, rather than explaining a delay after the fact.

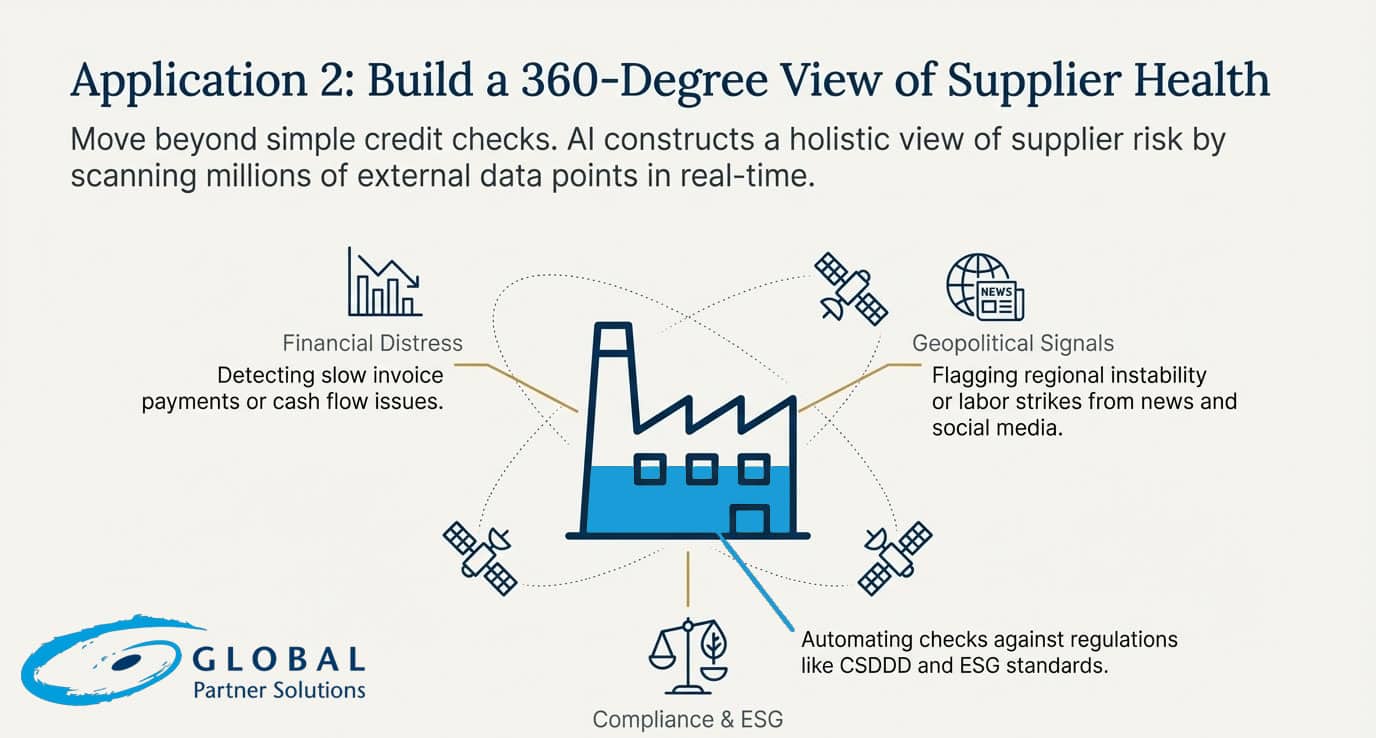

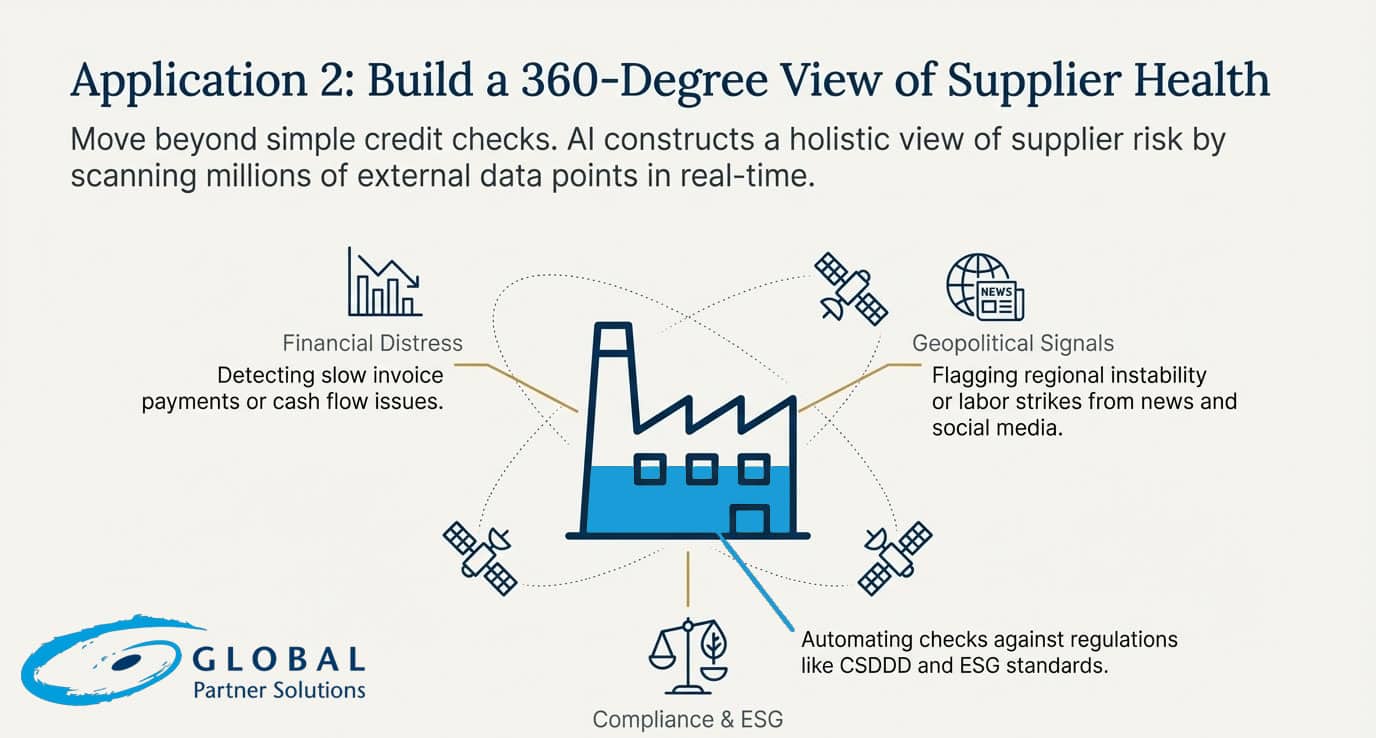

B. Holistic Supplier Health Monitoring

Moving beyond simple credit checks, AI constructs a 360-degree view of supplier risk by scanning millions of data points, including:

- Financial Distress: Detecting slow invoice payments or cash flow issues early.

- Geopolitical Signals: flagging regional instability or labor strikes via news and social media analysis.

- Compliance: Automating checks against regulations like the CSDDD and ESG standards.

Case in Point: A global fast-food chain used AI to identify alternative suppliers in Europe to mitigate Brexit risks. The result was a 25% reduction in network distance and €3.2 million in annual savings.

C. Automated Quality Control (Computer Vision)

Computer Vision (CV) technologies are revolutionizing performance management. By installing CV-enabled cameras on production lines, organizations can:

- Detect product defects with superhuman accuracy.

- Trace defects instantly to their source.

- Replace subjective quarterly reviews with objective, real-time quality data.

4. The Business Case: ROI by the Numbers

Investing in AI for supply chain risk is not a cost center; it is a value generator. Early adopters are already seeing significant financial impacts.

- 2x to 5x ROI: Organizations are achieving substantial returns on AI procurement investments.

- 58% Faster Cycle Times: Procurement teams utilizing Generative AI are accelerating workflows significantly.

- 80% Efficiency Gain: AI can reduce the time required for basic procurement tasks (like data entry) by up to 80%, freeing professionals for strategic work.

- Working Capital Improvement: Pentair, a global manufacturing firm, unlocked $15 million in working capital by using AI to gain clearer spend visibility and optimize payment terms.

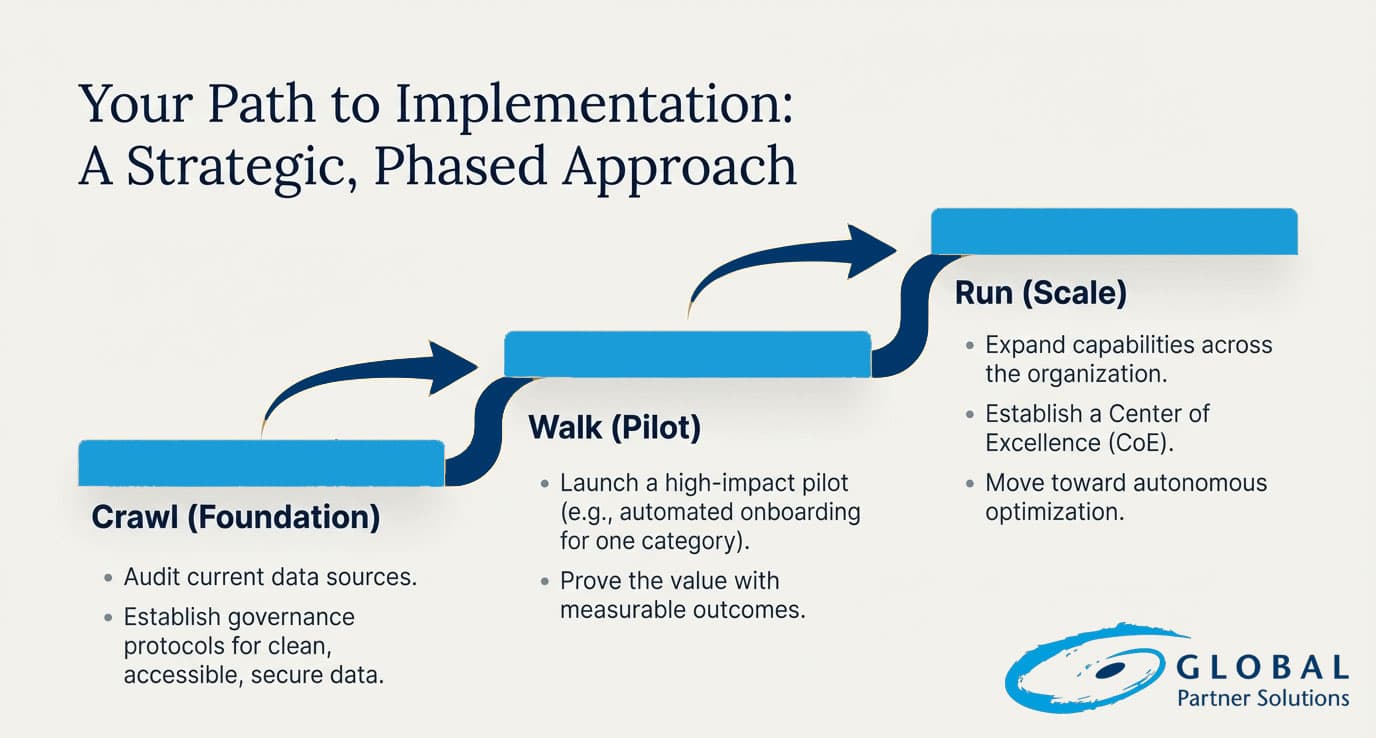

5. The Implementation Roadmap: Crawl, Walk, Run

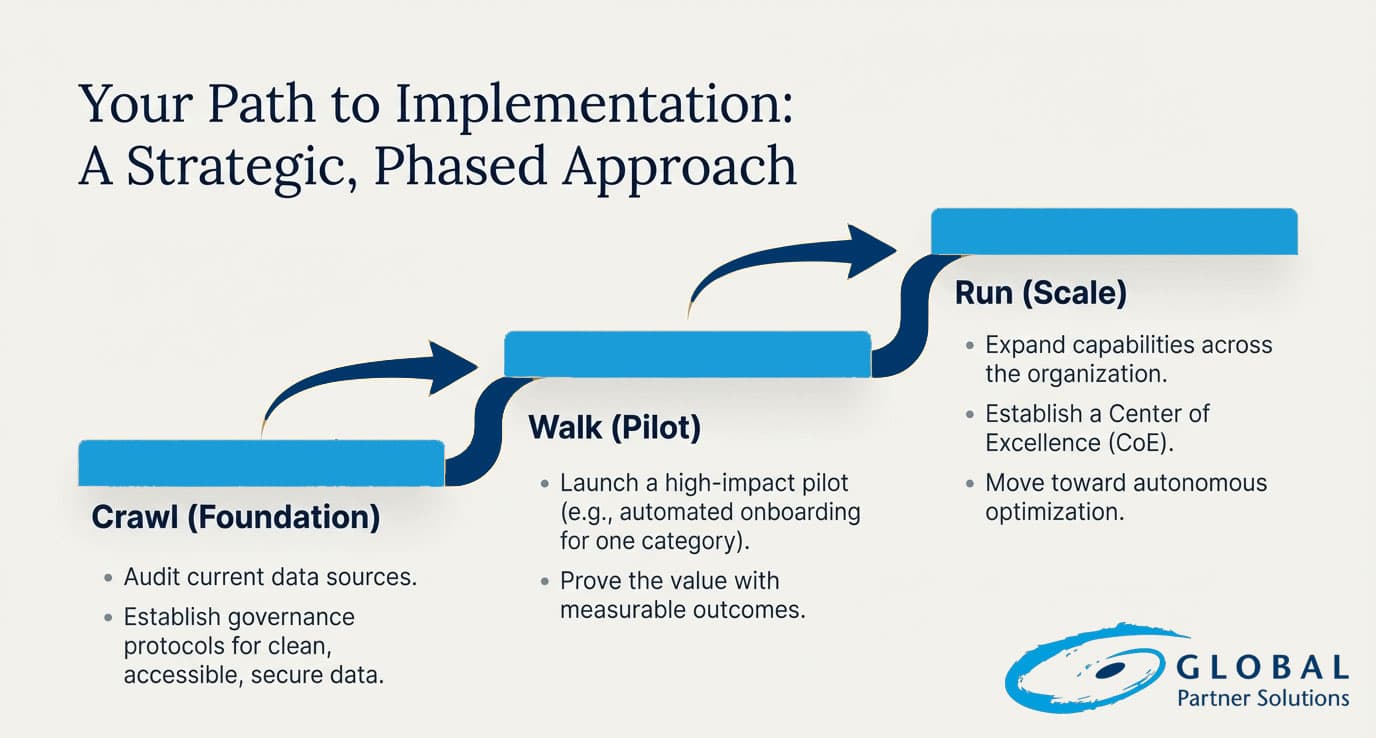

Implementing AI requires a strategic approach to navigate data quality issues and legacy system integration. A phased methodology ensures success:

- Crawl (Foundation): Audit current data sources. Establish governance protocols to ensure data is clean, accessible, and secure.

- Walk (Pilot): Launch a high-impact pilot (e.g., automated onboarding for one category). Prove the value with measurable outcomes.

- Run (Scale): Expand capabilities, establish a Center of Excellence (CoE), and move toward autonomous optimization.

Conclusion: The Strategic Imperative

The distinction between market leaders and laggards is no longer defined by if they adopt AI, but by how they embed it into their operational DNA.

AI does not replace the expert judgment of procurement professionals; it empowers them. By handling the immense complexity of data analysis and providing a proactive shield against risk, AI allows supply chain leaders to focus on what matters most: strategy, resilience, and growth.